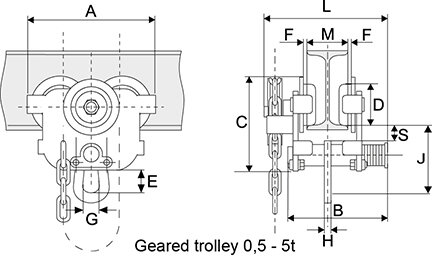

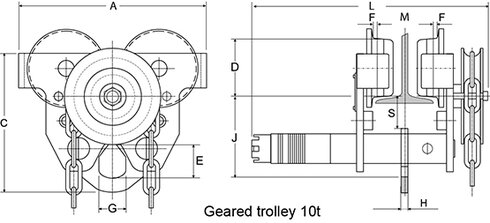

Powertex Geared Trolley PGT-S2 is a high quality, durable low built push trolley that is easy to install on horizontal beams and rails.

The trolleys can be used for I-beams with plane flanges (such as IPE, HEA or HEB types) or beams with sloping flanges (such as INP-beams).

The trolley can easily be positioned along the beam using the hand chain thanks to high quality steel wheels with bearings.

Features:

- Safe - All Powertex trolleys are proof load tested 1,5 x WLL

- Mechanical stops integrated in the design to prevent derailing

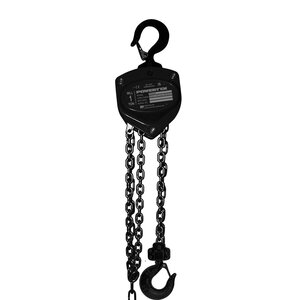

- Equipped with connection plate with eye to hoist’s upper hook or direct connection

- Connection plate can be turned 90 degrees to allow direct connection to Powertex S2 hoists without need of intermediate hook/eye

- Rubber bumpers to absorb shock loads on impact to rail ending

- Equipped with RFID for quick registration and maintenance

- Marked with QR code to allow access to User manuals at any time

- PGT-S2 is easy to mount and dismount on a horizontal rail or beam

- The 3 piece design makes installation quick and ergonomically

- The shaft is easily locked using the Lock plate (No need to use large castle nut nor collar pins)

- Wheel shafts are robotic welded for high quality weld seams

- Large steel wheels equipped with double sided sealed bearings that do not need maintenance

- Powder painted side panels gives a nice lasting finish

- Fits most types of beam profiles and most brands of lifting blocks and electric hoists

- Longer shafts for wider beams can be supplied from stock in EU

- Can be turned into Blackline version BT by adding the included grey label over the shiny nameplate

Option:

- Black painted hand chain instead of galvanized hand chain

Blackline products are suitable to be used in theatres and entertainment industry.

Note on entertainment & theatre applications: Powertex Trolleys are designed and certified according to industrial lifting standards (EN 13157)

For any application where loads are suspended above people (e.g., theatre, stage, rigging), please ensure that the complete installation meets the safety requirements of EN 17206

- Marking: According to standard, CE-marked, WLL, beam width, individual serial number

- Temperature range: -10°C up to +50°C.

- Finish: Black powder painted (Matt finish)

- Standard: EN 13157

- Safety factor: 4:1

Legal Documents

Additional Documents