Chain slings – basics, construction, and standards

Chain slings are indispensable tools in material handling and lifting heavy loads in industries such as construction, logistics, metallurgy, and manufacturing. Their main advantages include durability, resistance to mechanical damage and high temperatures, and the ability to operate in demanding working conditions.

What is a chain sling made of?

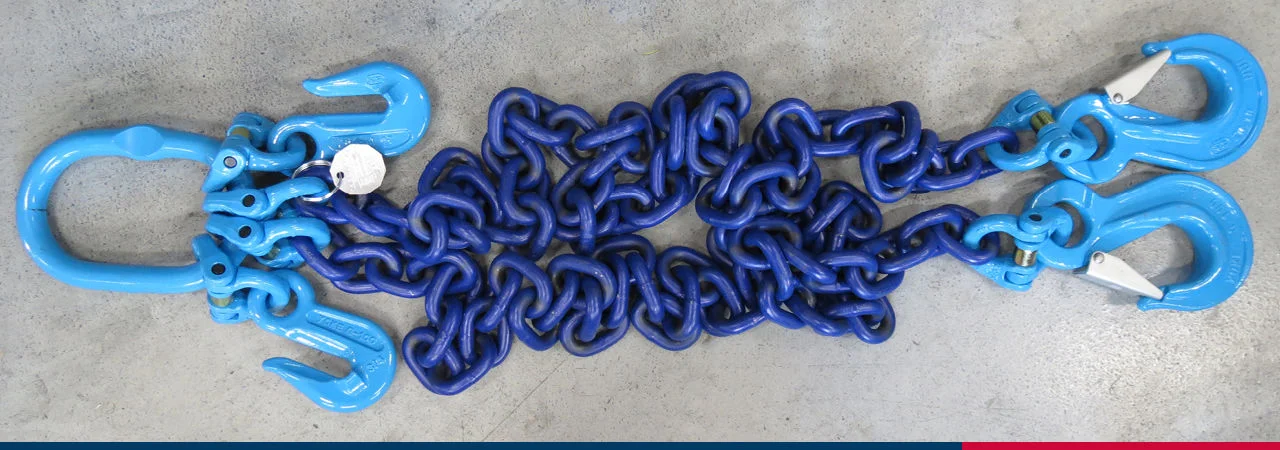

A typical chain sling consists of several main components:

- Master link – connects the sling to the hook of a crane, hoist, or other lifting device,

- Chain legs – made of high-quality steel, responsible for carrying the load,

- Assmebly links – used in multi-leg configurations,

- Hooks – enable attachment of the load (they can be standard, safety, shortening, swivel, etc.),

- Additional components – such as shortening clutches, couplers, or specialized hooks.

Thanks to their modular design, slings can be adapted to a wide variety of applications and loads – from concrete prefabricated elements to steel structures and machinery.

Chain strength classes

Chains used in slings are divided into strength classes, which determine their load capacity and resistance to tensile stress:

- Grade 8 – standard, commonly used in industry,

- Grade 10 – higher load capacity with the same chain diameter,

- Grade 12 – for the most demanding applications where compactness and high strength are required.

Choosing the right class is crucial for the safety and durability of the sling.

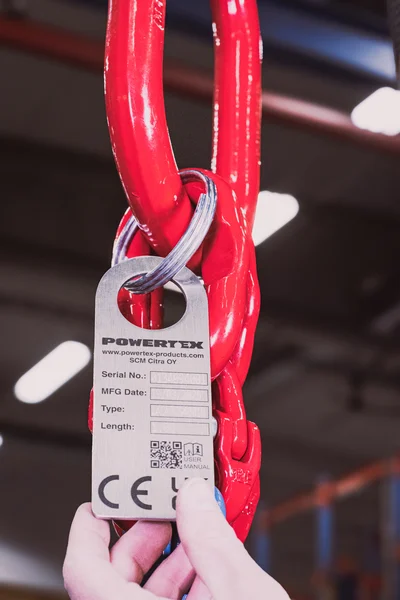

Standards and certifications

Chain slings must meet European quality and safety standards. The most important ones include:

- EN 818 – covering chains and chain slings,

- EN 1677 – relating to components such as hooks, links, and connectors.

All components should bear appropriate markings (e.g., batch number, grade, manufacturer) and documentation confirming compliance with standards – this ensures that the sling meets strict requirements and can be used safely.

| Grade | Material strength | Load capacity for the same diameter | Application |

|---|---|---|---|

| 8 | ok. 800 MPa | standrad | industry, construction |

| 10 | ok. 1000 MPa | +25 % in relation to grade 8 | heavy loads |

| 12 | ok. 1200 MPa | +50 % in relation to grade 8 | extreme conditions, heavy industry |