Steel wire rope maintenance and inspection

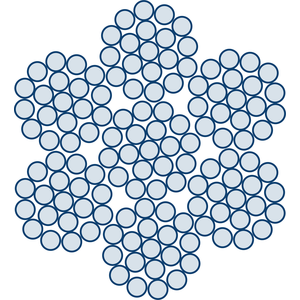

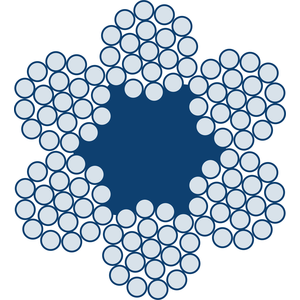

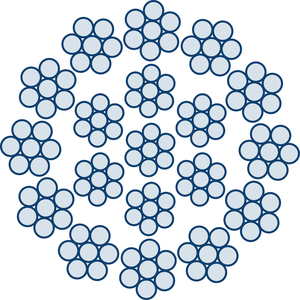

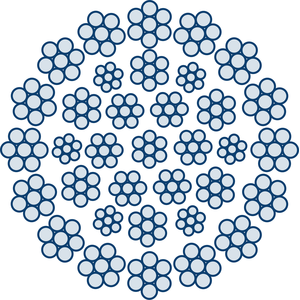

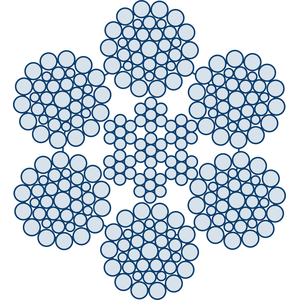

Steel wire ropes are complex lifting tools, constructed around a core surrounded by twisted layers of steel wires. The wires and strands can be twisted either to the right or to the left, and their number, arrangement, and method of manufacture have a direct impact on the rope’s strength, flexibility, and resistance to fatigue.

During operation, especially under load, individual wires and strands move relative to each other, causing internal friction. In addition, the rope is exposed to external factors such as weather conditions, temperature changes, contaminants, and mechanical wear caused by contact with drums and sheaves.

Before first use, ensure that the rope matches the order, has no damage, and that its diameter, certificates, and intended purpose comply with the requirements. It is equally important to verify that the equipment the rope will work with is fully operational. In particularly hazardous conditions, such as lifting people, offshore operations, or transporting dangerous goods, a risk assessment is required, along with appropriate adjustment of operating parameters, including the safe working load.

Rope installation

Unwinding and installing the rope must be carried out with caution. The rope must not be pulled from a stationary reel, as this leads to twisting (kinks) that permanently damage the internal structure. Rotating stands or guides should be used, and the winding direction must be maintained.

If the rope needs to be cut, it must be secured with clamps on both sides of the cutting point — for rotation-resistant ropes, at least two clamps of a length not less than twice the rope’s diameter should be used. Cutting should be performed with specialised tools, and the securing should remain in place until the ends are permanently fixed.

Before starting operation, a newly installed rope should be run in under a light load so that it adapts to working conditions. During installation, attention should also be paid to the correct lay direction in relation to the drum winding and to maintaining proper fleet angles, as these have a significant impact on rope wear.

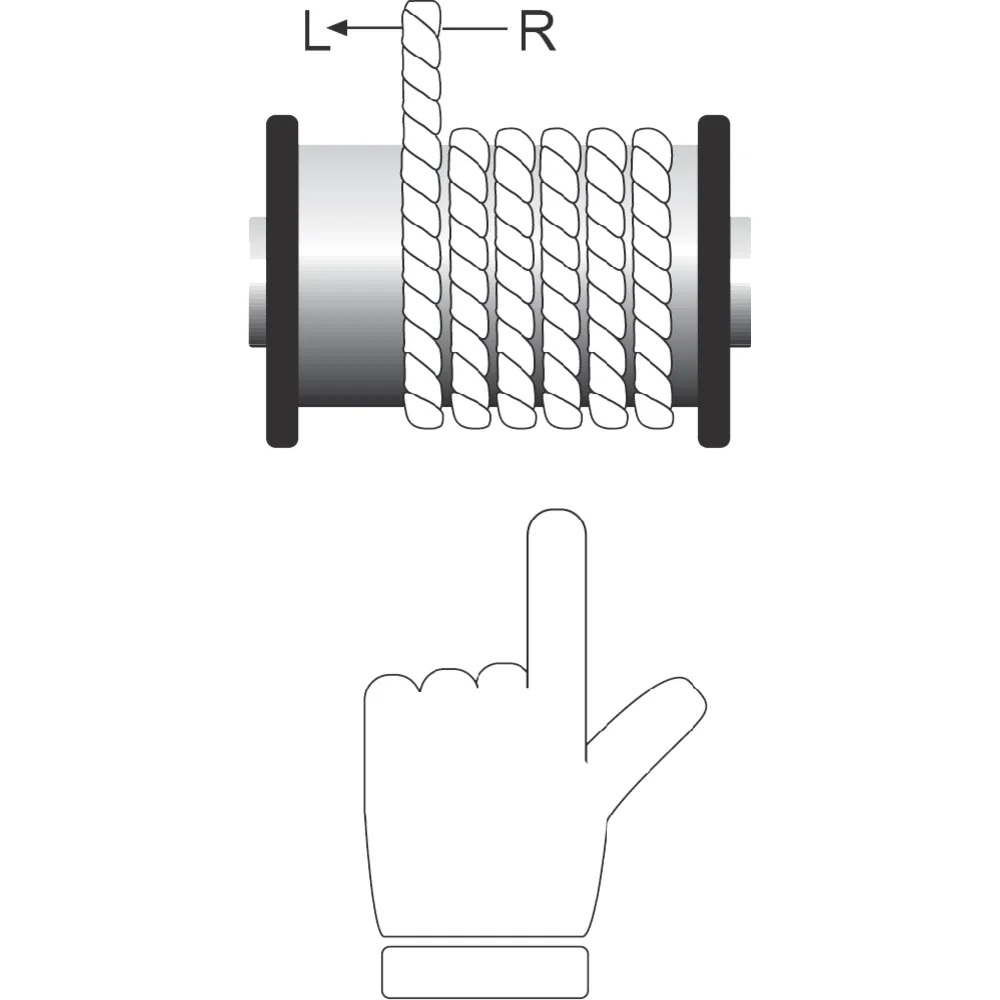

The drum’s groove direction and the rope’s anchoring point determine whether a right-lay or left-lay rope should be used. The rule is simple:

-

Right-hand grooved drum – use a left-hand lay rope.

-

Left-hand grooved drum – use a right-hand lay rope.

WARNING! Incorrect selection of rope lay direction can significantly shorten its service life. When spooling, ensure that each wrap lies fully in contact with the drum surface or the previous layer. If necessary, apply proper braking to the supply reel.

WARNING! Incorrect selection of rope lay direction can significantly shorten its service life. When spooling, ensure that each wrap lies fully in contact with the drum surface or the previous layer. If necessary, apply proper braking to the supply reel.

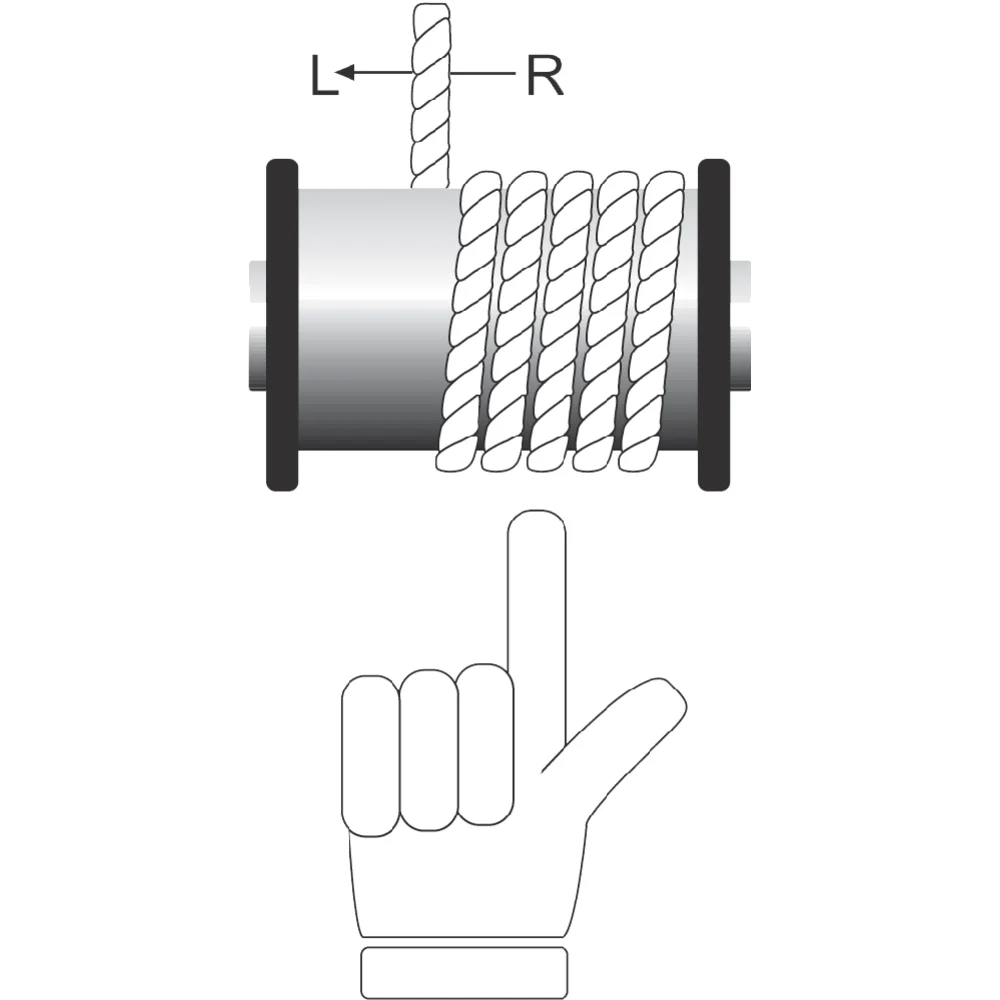

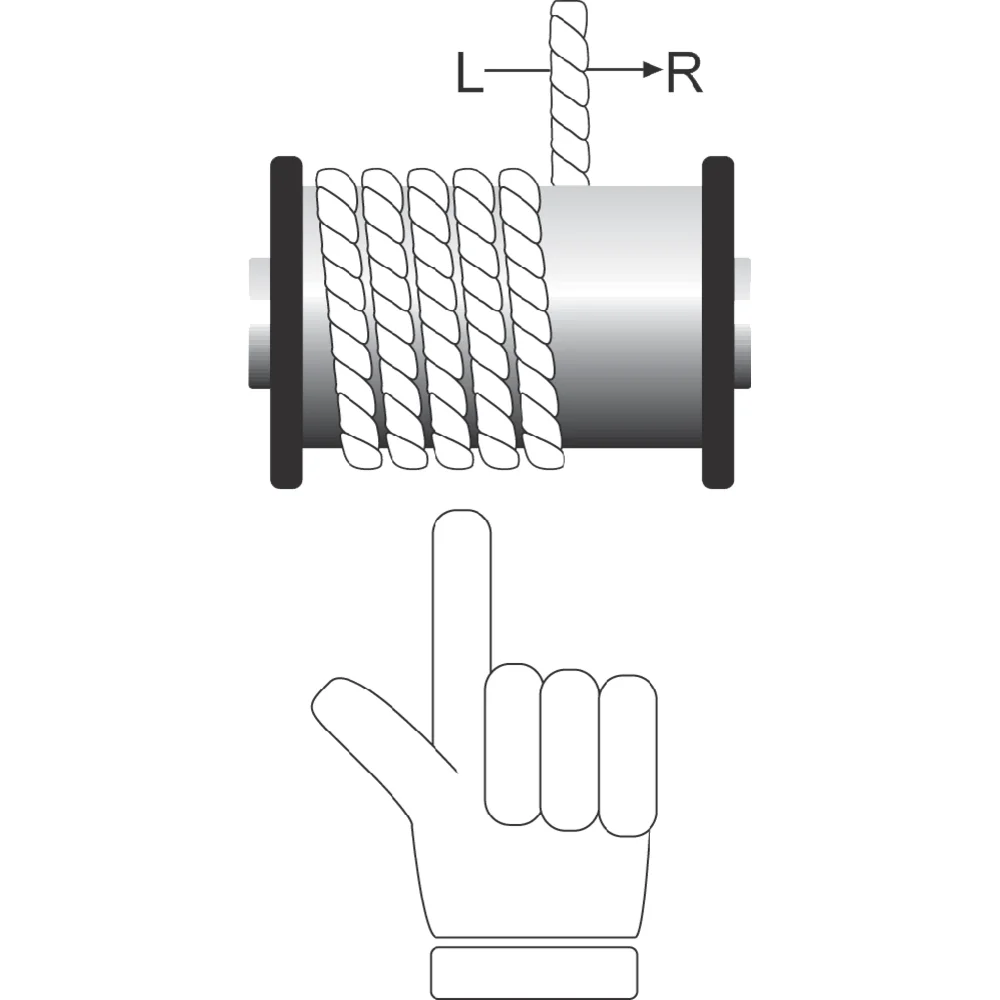

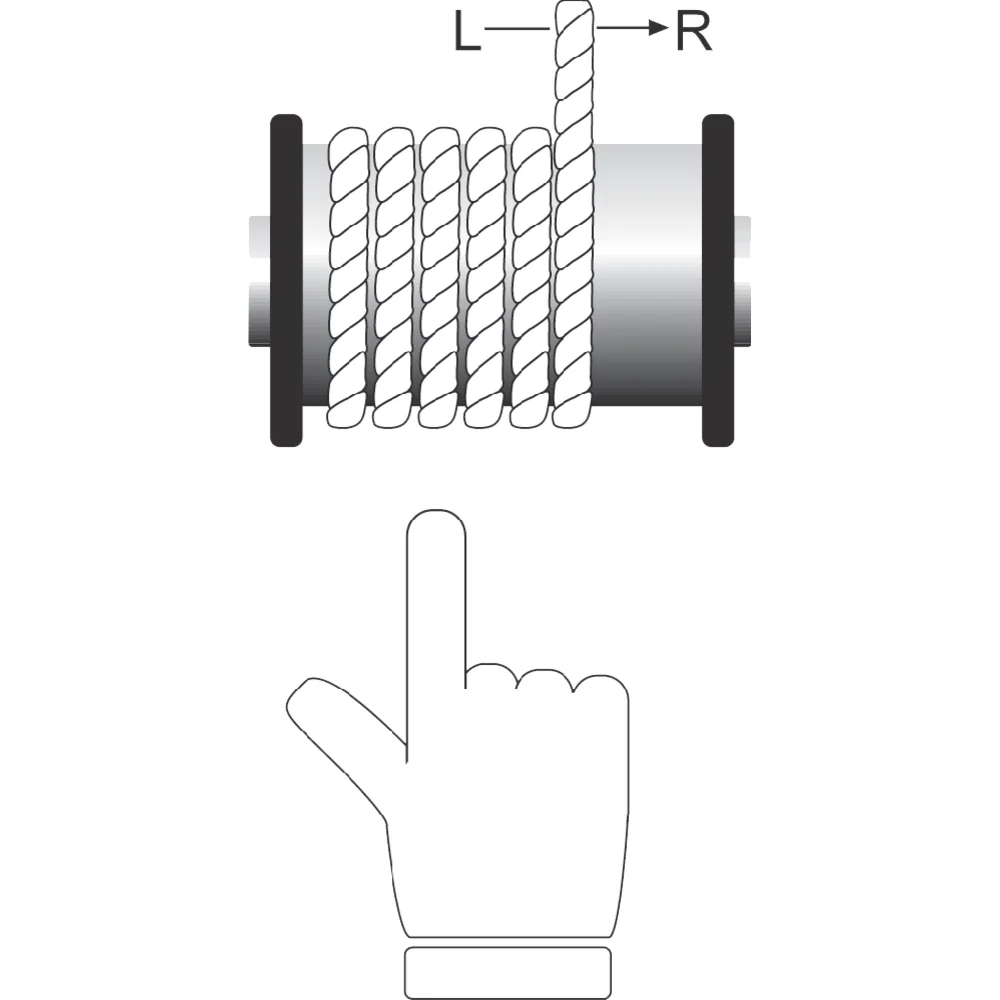

The winding direction shown in the diagrams below applies to both smooth and grooved drums.

Underwinding

Overwinding

Right-hand rope – from right to left

Left-hand rope – from left to right

Right-hand rope – from left to right

Left-hand rope – from right to left

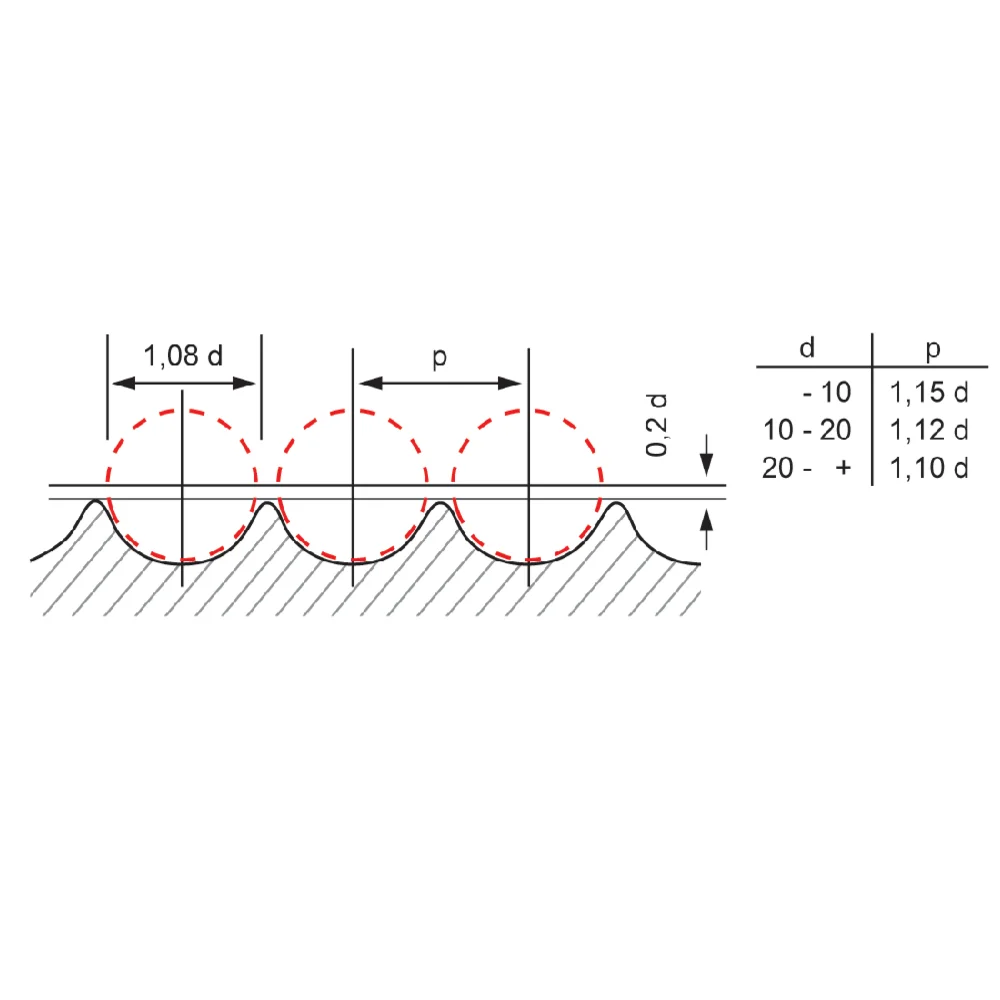

Grooving

Before installation, the general technical condition of the drum must be checked. For a grooved drum, the groove radius and pitch should be verified to ensure they match the diameter of the new rope.

If the drum diameter is too small, it can cause permanent rope deformation, which almost always results in the need for premature replacement.

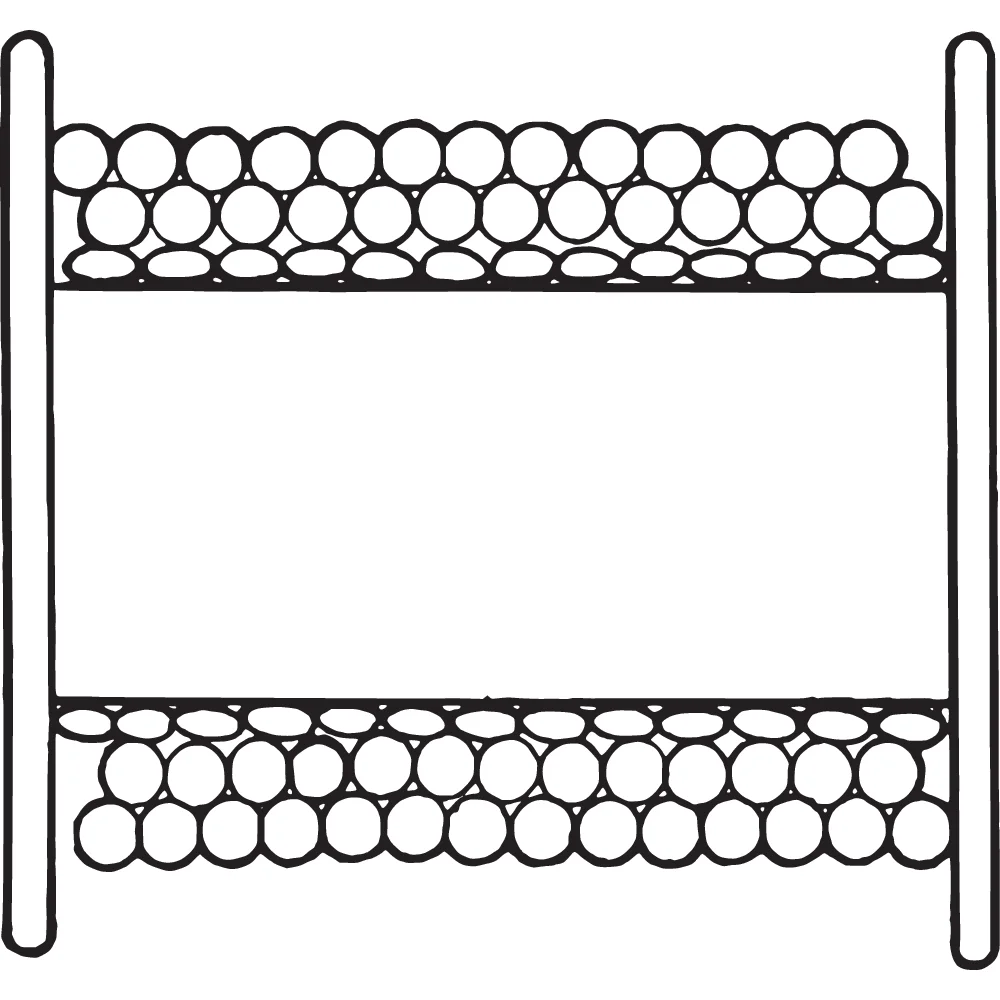

Multiple layers

Using multiple layers of rope on a drum can lead to flattening and deformation of the lower layers, especially if an unsuitable rope construction is used or if winding errors occur.

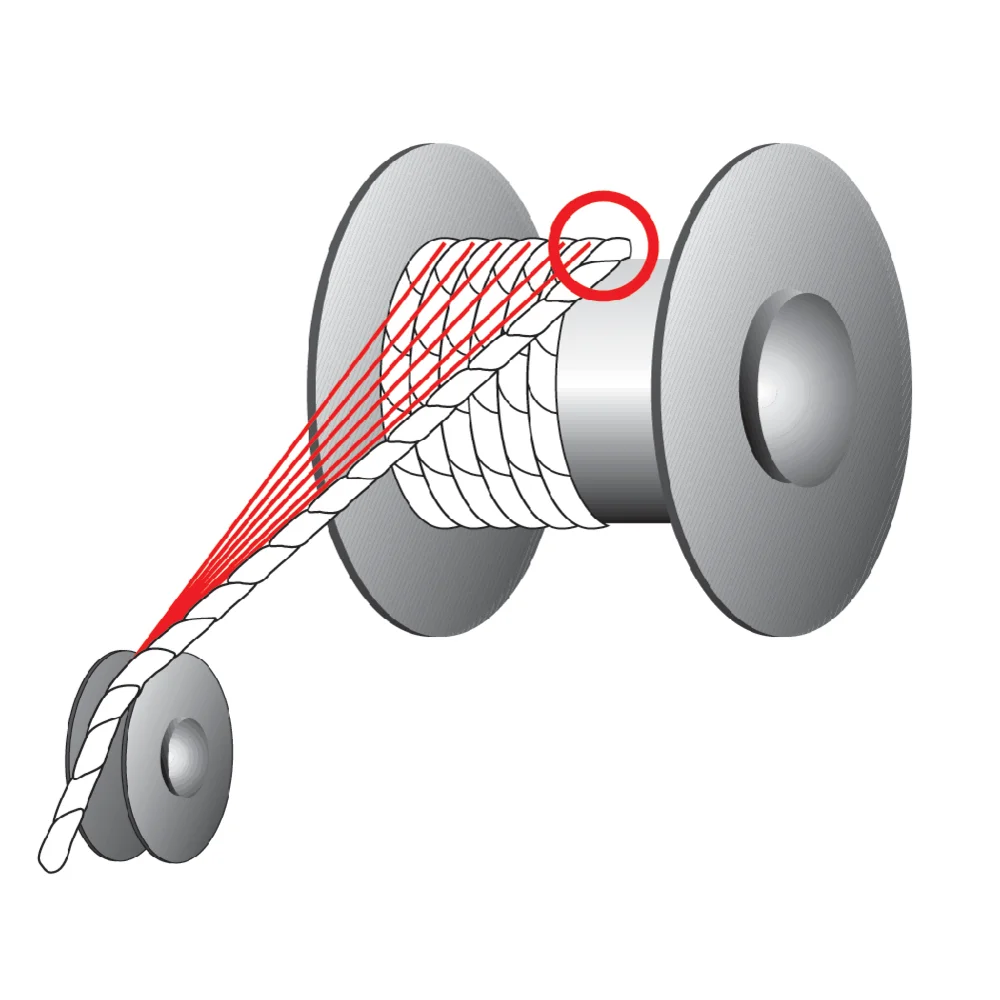

Fleet angle

An excessive fleet angle can cause intensive abrasion between adjacent rope wraps on the drum. It can also lead to twisting issues and rope deformation.

Capacity

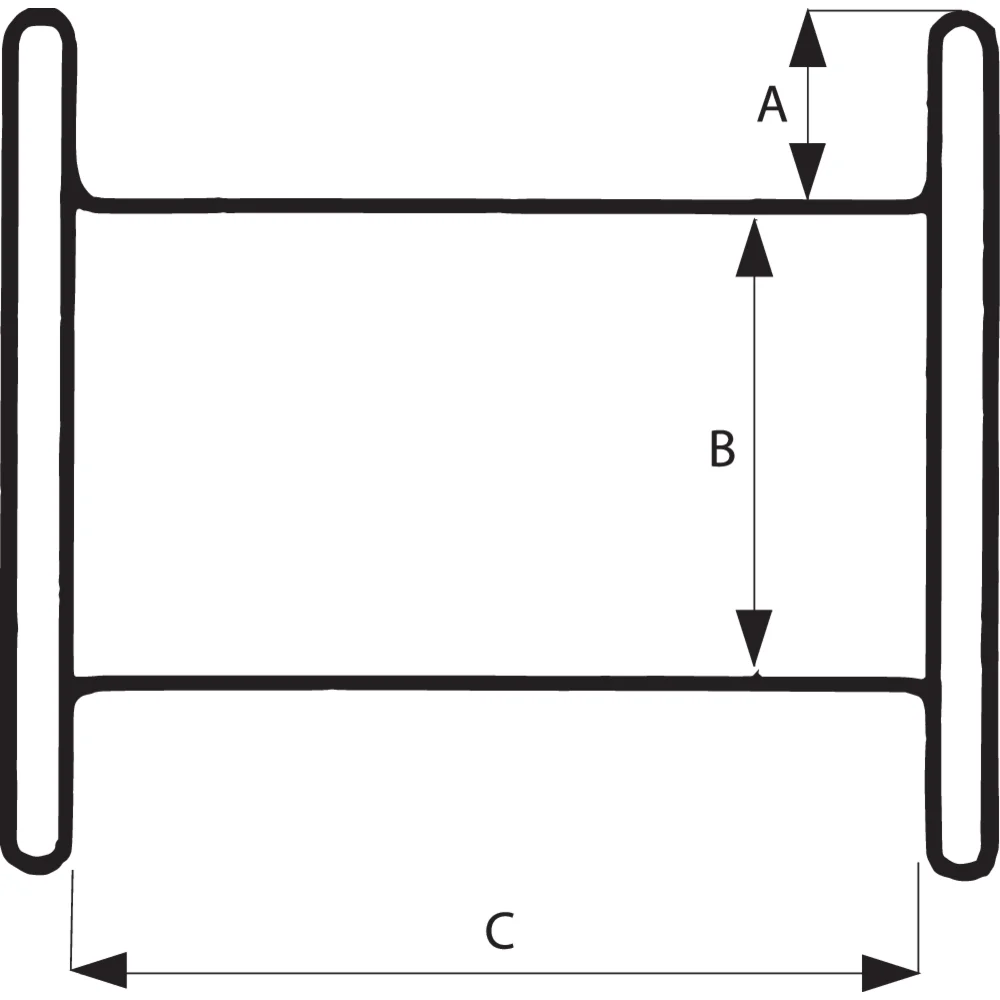

The following formula can be used to estimate the length of rope of a given diameter that can be wound onto a drum:

Rope length (m)=d2(A+B)×A×C×π×106

where:

- A, B, C – in metres

- d – rope diameter in millimetres

Note: New ropes may be manufactured with a positive diameter tolerance of up to 5%.

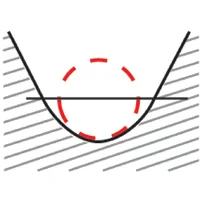

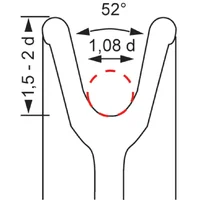

Before installing a new rope, the condition of the grooves, bearings, and lubrication of the sheaves should be checked. The groove diameter should be measured using a radius gauge. The recommended groove diameter should be between 108% and 114% of the rope diameter (i.e. 0.54–0.57 × d).

Worn sheaves should be replaced or refurbished.

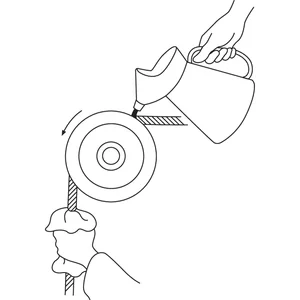

Rope lubrication

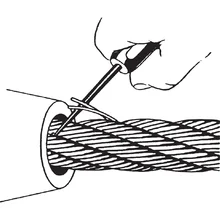

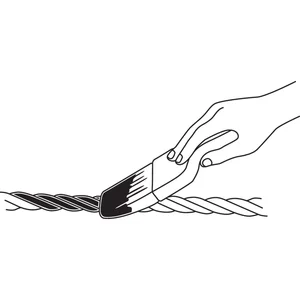

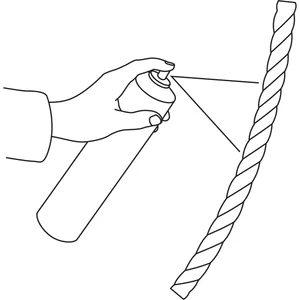

Regular lubrication is a key element of steel wire rope maintenance. During manufacturing, the rope is coated with a protective grease that only protects it during transport and storage. Before first use, lubrication should be replenished with a suitable product intended for operational conditions. The rope should first be thoroughly cleaned of any remaining old grease, rust, and contaminants. Lubricants can be applied using sprayers, brushes, manual applicators, or special pressure devices. The best results are achieved with a high-pressure lubrication machine, which allows the product to penetrate deep into the rope core.

The lubrication frequency depends on working conditions, temperature, usage intensity, number of bending cycles, and rope type. In typical industrial applications, lubrication is recommended three to five times over the rope’s service life. Excess grease is undesirable — it can contaminate equipment, cause internal rope corrosion, and lead to material waste. To estimate the required amount of lubricant, an appropriate formula considering the rope length and diameter can be used.

Rope inspection

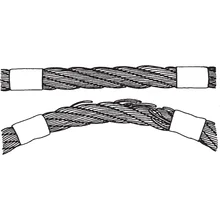

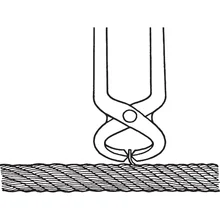

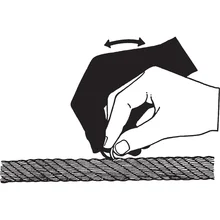

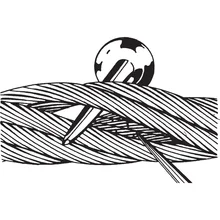

The technical condition of the rope should be checked daily by the operator and periodically by a qualified person. Particular attention should be paid to sections exposed to intensive use, including contact zones with sheaves, terminations, and areas operating on the drum. Signs of wear include broken wires, abrasion, flattening, deformation, kinks, and signs of corrosion. Visible damage should result in the rope being withdrawn from service. Individual broken wires may be removed by bending the wire so that the break occurs inside the rope structure, preventing protruding ends.

The rope must be discarded in accordance with applicable standards or the manufacturer’s recommendations. The final decision to withdraw a rope from service may only be made by a person with the appropriate qualifications and knowledge. Exceeding the permissible number of wire breaks, a reduction in diameter, deformations, or other signs of material fatigue are clear indicators that the rope must be replaced. For ropes used with plastic sheaves, internal damage may occur before it becomes visible externally — in such cases, an individual inspection schedule should be developed based on operational data.

Regular maintenance, proper lubrication, correct storage, and adequate operator training are crucial for the safety and efficiency of steel wire rope operation.