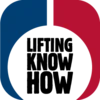

What is a steel wire rope made of?

A steel wire rope is made up of individual steel wires twisted together to form strands, which are then wound around a central core. This construction provides an optimal balance of strength, flexibility, and resistance to wear.

The core of the rope can be made of steel or fibre (natural or synthetic) and plays a key role in maintaining the shape and load-bearing capacity of the entire structure.

The combination of the number and diameter of wires in a strand determines the rope’s performance characteristics:

-

Thicker wires provide higher resistance to abrasion and corrosion.

-

Thinner wires increase flexibility and ease of handling.

The construction of a rope is described using designations such as 6x36-FC, where:

-

6 – number of strands in the rope

-

36 – number of wires in one strand

-

FC (Fibre Core) – type of core, in this case fibre

Thanks to the variety of constructions, steel wire ropes can be precisely matched to specific applications — from simple lifting systems to advanced industrial installations.

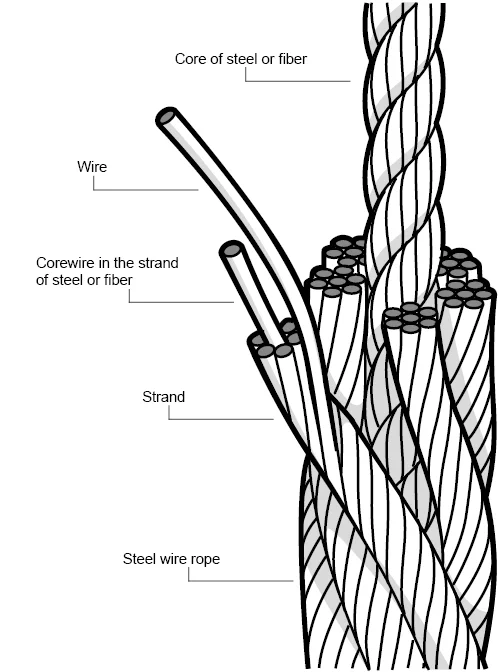

From wire to steel rope

The illustration on the right shows how steel wire is made and the processes it undergoes before it can be wound onto a drum.

Steel wire

The starting material is wire rod, which is cold-formed into various sizes and strength grades.

The most common grades are:

ChatGPT powiedział:

| Rope grade EN | Tensile strength grade of wire – API 9A |

Hardness app. Min. kp/mm² |

Min. N/mm² | Max. kp/mm² | Max. N/mm² | Brinel HB | Rockwell HRC |

| 1570 |

PS

|

140

|

1370

|

180

|

1770

|

405/425

|

45

|

| 1770 |

IPS

|

160

|

1570

|

200

|

1960

|

445/470

|

49

|

| 1960 |

EIPS

|

180

|

1770

|

220

|

2160

|

470/480

|

51

|

| 2160 |

EEIPS

|

200

|

1960

|

220

|

2160

|

480/500

|

52 |

External treatment: The wire is generally either uncoated (bright), galvanized, or stainless. Galvanizing provides good protection in particularly corrosive environments. In extreme cases, stainless steel wire is used. Steel wire ropes can also be fitted with a plastic coating for additional external protection.

Core

A steel wire rope is a construction made up of many thin wires that form strands, which are then twisted around a core. Both the arrangement of the wires within a strand and the rope’s overall construction have a significant impact on its properties, including flexibility, resistance to abrasion, stretching, and crushing.

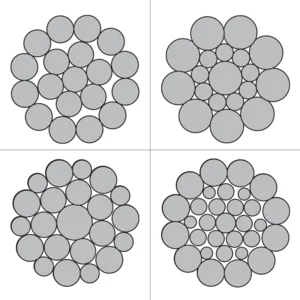

Types of rope strands:

-

Isowire – all wires have the same diameter and are cross-laid. This is the simplest and most uniform arrangement.

-

Seale (S) – wire layers are arranged in parallel. The outer and inner layers contain the same number of wires but with different diameters — thicker on the outside, thinner inside.

-

Warrington (W) – the outer layer contains wires of two different diameters, which helps fill the gaps more effectively and increases durability.

-

Warrington-Seale (WS) – a combination of Seale and Warrington; the strand contains three or more layers of wires for increased load capacity and resistance.

-

With fillers (F) – thin filler wires are placed between layers to increase density and reduce wear.

-

Compacted strand – after twisting, the strand undergoes additional mechanical processing (pressing, rolling) to create a more compact structure.

Linear contact strands

In a strand construction using several layers of wires of the same diameter, the layers intersect with each other — this is known as point contact. Such a design is simple to produce but limits the load-bearing surface of the wires in the cross-section.

In contrast, constructions that use wires of different diameters have layers arranged parallel to each other, creating what is called linear contact. Strands of this type have a larger steel cross-sectional area, which translates into higher load capacity. An additional advantage is better fatigue resistance and increased wear durability. This is because all wires have the same lay length and the same lay angle within the strand, ensuring even load distribution during rope operation.

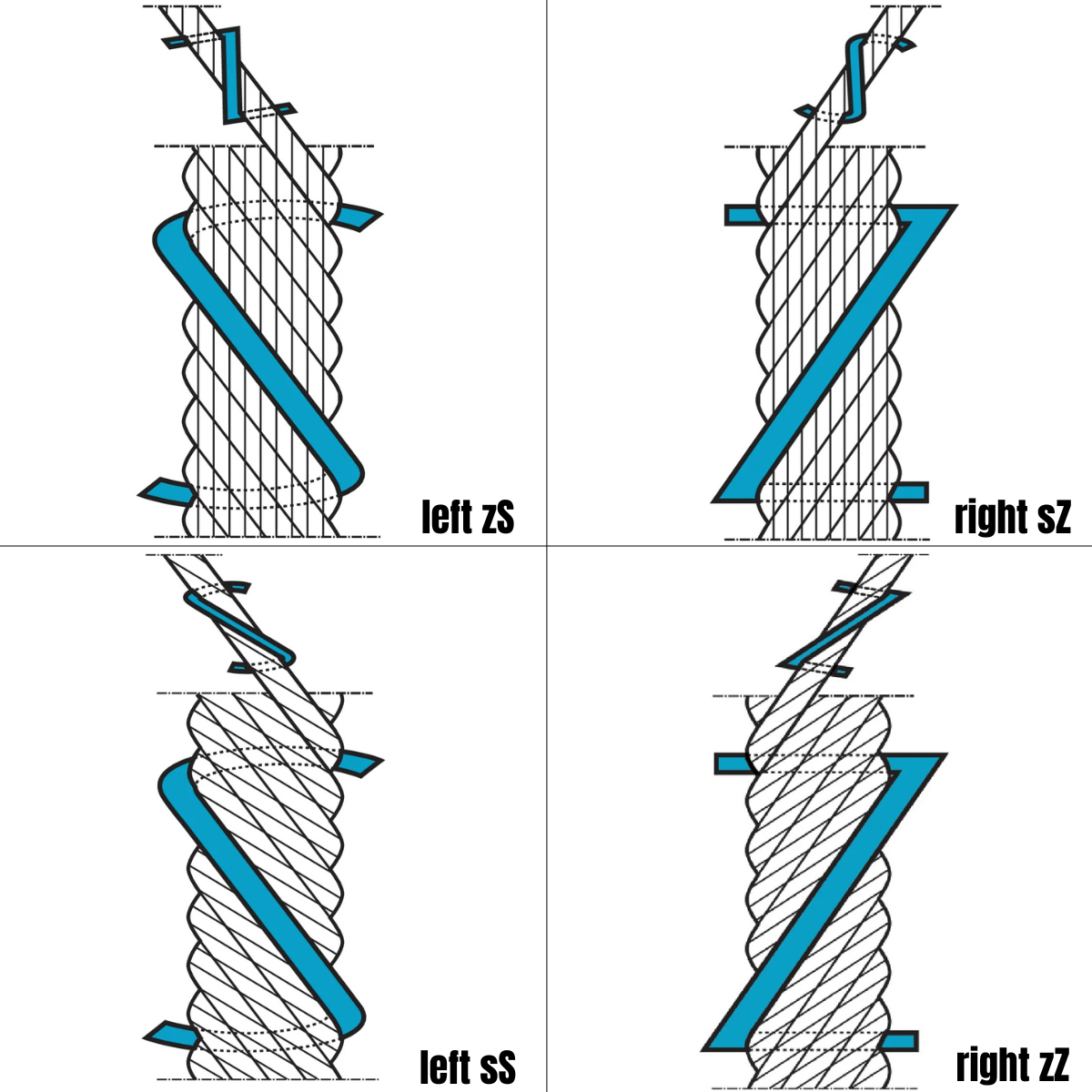

Types of lay

The term lay refers to the direction in which the wires within the strands are twisted and the direction in which the strands themselves are laid around the rope’s core. The way these directions combine has a significant impact on the rope’s behaviour during operation.

Regular lay – The direction of the wire twist in the strand is opposite to the direction in which the strands are twisted around the rope’s core.

Advantages:

-

Better structural stability

-

Greater resistance to rotation and deformation

-

Reduced risk of rope unlaying

-

Higher permissible number of wire breaks

-

Easier identification of broken wires

Lang lay – The direction of the wire twist in the strand is the same as the direction in which the strands are twisted around the rope’s core.

Advantages:

-

Larger load-bearing surface and improved wear resistance

-

Excellent contact with sheave grooves

-

Better performance on multi-layer drums

-

Longer service life under high self-weight loads

Note: Lang lay ropes generate higher torque — they should not be used in applications where the rope can rotate freely.

Lay directions:

-

Right-hand lay (zZ) – Wires and strands are twisted to the right around the core. This is the most common lay direction.

-

Left-hand lay (sS) – Wires and strands are twisted to the left around the core; used less frequently, usually in special applications.

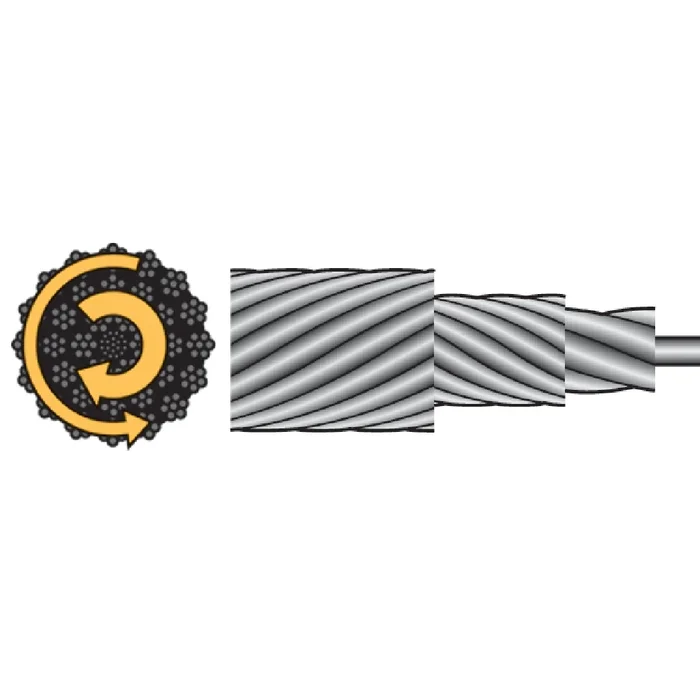

Rotation-resistant steel wire ropes

When working with high lifting heights, especially in tower cranes, construction hoists, or mobile cranes, it is crucial that the rope does not rotate around its own axis. Excessive twisting can lead to tangling, load damage, or even equipment failure. To prevent this, rotation-resistant ropes are used.

How it works:

Rotation-resistant ropes are made of multiple layers of strands, with each layer twisted in the opposite direction to the one beneath it. For example, if the inner layer has a right-hand lay, the next layer will have a left-hand lay — and so on alternately.

Thanks to this design:

-

The torque from individual layers cancels out,

-

The rope does not twist under load,

-

High directional stability is maintained,

-

Lifting safety and precision are significantly improved.

Preforming of steel wire rope

Preforming is a manufacturing process in which the wires and strands of a steel wire rope are shaped before the final closing of the rope. During this process, each component is given the spiral form it will have in the finished product. This is done in a special preforming head, just before the stranding stage.

Advantages of preforming:

-

Reduces internal stresses – the wire becomes more stable and easier to handle,

-

The rope does not tend to twist or unlay uncontrollably,

-

After cutting, strand ends retain their shape – no need for binding,

-

Easier installation and safer use.

Lay length

Lay length refers to the distance in which a wire or strand makes one complete turn around the rope’s core. It is a key parameter of any rope design, precisely determined during the manufacturing stage.

Changing the lay length can drastically shorten the rope’s service life, which is why it must not be altered during operation or reworking.

Breaking load – Minimum breaking force

This is the lowest force value, expressed in kilonewtons (kN), that a rope must withstand to meet the requirements of standards and be approved for use.

Calculated breaking load

This is the theoretical value calculated as:

total steel cross-sectional area × tensile strength of the wire.

The calculation does not take into account losses resulting from the effects of wire twisting, meaning that this value is indicative only. In practice, meeting the standard for the minimum breaking force is of key importance.