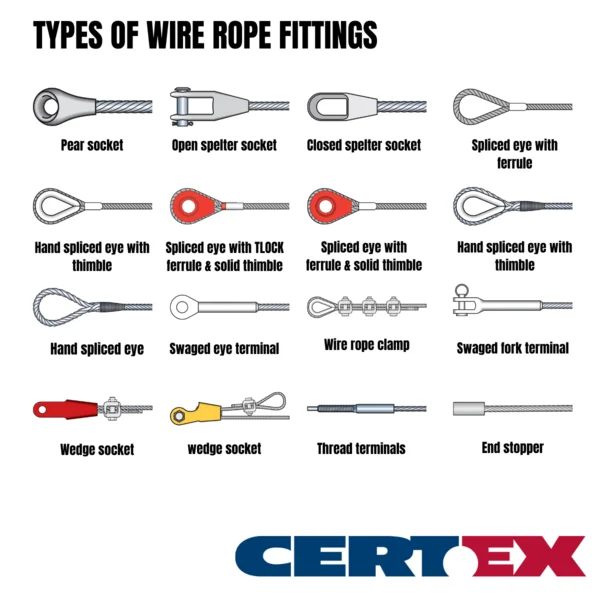

Sockets, meaning steel wire rope terminations poured with resin or zinc, are among the most reliable solutions in lifting and securing systems. Thanks to their design and the correct pouring process, they retain 100% of the rope’s safe working load (SWL). They feature high load capacity, resistance to dynamic overloads, and minimal working elongation.

They are used in cranes, engineering structures, and the offshore industry — wherever durability and safety are critical. The key factor is selecting the right type of socket for the rope’s diameter, construction, and operating conditions.

Steel wire rope terminals are durable end fittings crimped onto the rope using a press. They are used in structural and architectural fastening systems, where both strength and connection aesthetics are important.

Depending on the application, various types are available — fork terminals, eye terminals, and swage studs with threaded ends. When correctly crimped, terminals provide a minimum breaking strength equal to 90% of the rope’s average tensile strength, making them a reliable solution for many engineering applications.

A thimble eye secured with wire rope clips is a popular method of forming a rope termination, most often used in simple, less demanding applications. It consists of several basic components: bolts, clips, and nuts, which together create a durable connection. The assembly is used to form a loop at the end of the rope, while the thimble additionally protects the rope from abrasion and crushing.

Depending on the type and number of clips used, the minimum breaking strength of such a termination is 90% of the rope’s average tensile strength. To ensure safety and effectiveness, it is crucial to use the appropriate clips and to install them correctly in accordance with the manufacturer’s technical documentation.

Steel wire rope ferrules are a reliable solution for creating durable and safe terminations. Crimped sleeves fitted onto the rope allow for a variety of end configurations — from standard to specialised, designed for work in demanding conditions.

All types of ferrules, when correctly crimped onto the rope, provide a minimum breaking strength of 60–80% of the rope’s average tensile strength. To ensure safety and connection performance, it is essential to use the correct type of ferrule and to install it properly in accordance with the manufacturer’s technical documentation.