Accurate measurement of steel wire rope diameter is essential for its safe use and compliance with technical requirements.

How to correctly measure rope diameter:

-

Perform the measurement on a straight, undamaged section of the rope before installation.

-

Take measurements in two different locations, at least one metre apart.

-

At each location, measure the diameter twice, rotating the caliper jaws by 90°.

-

Calculate the arithmetic mean of the two readings for each measurement point.

-

The resulting value should fall within the tolerance range specified in the standard, as shown in the tables below.

Correct measurement and adherence to tolerances ensure the rope is safely matched to the sheaves, drums, and load-bearing components of lifting equipment.

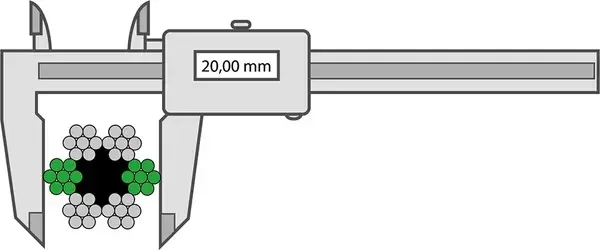

The correct way to measure

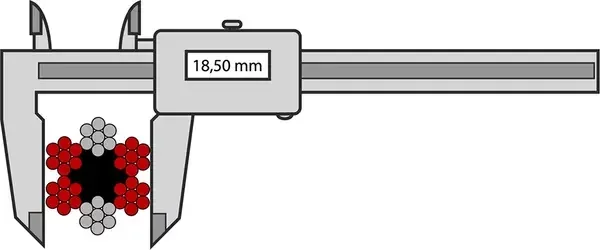

Incorrect measurement method

Why is diameter measurement so important?

- A rope diameter that does not match the grooves of sheaves, drums, or guides can lead to premature wear of both the rope and the equipment.

- A rope that is too thin may slip, fall off the drum, or increase the risk of breakage.

- A rope that is too thick may jam, causing excessive friction or mechanical damage.

Permissible diameter tolerances

- For new ropes, the diameter may be slightly larger than the nominal value (e.g. +2%).

- Over time, the rope may wear or stretch, which will also affect the diameter measurement.

- Standards such as EN 12385 define precise tolerance ranges for different rope types and diameters.

Measuring instruments and measurement conditions

- Ideally, use a caliper or micrometer with an accuracy of up to 0.01 mm.

- Perform the measurement at room temperature, in a location free from dirt, grease, and mechanical damage.

- Compressed or deformed ropes should not be measured — instead, choose another undamaged section.

General-purpose steel wire rope

| Nominal rope diameter Ø | Diameter tolerance for an unloaded steel wire rope |

| Mm | % |

|

od 2 do <4

|

0 +8

|

|

od 4 do <6

|

0 +7

|

|

od 6 do <8

|

0 +6

|

|

8 i wyżej

|

0 +5

|

| Nominal rope diameter Ø | Nominal diameter tolerance for an unloaded rope | |

| Mm | Rope with strand parts made entirely of steel — maximum | Rope with strand parts containing a fibre core — maximum |

|

od 2 do <4

|

+7

|

-

|

|

od 4 do <6

|

+6

|

+8

|

|

od 6 do <8

|

+5

|

+7

|

|

8 i wyżej

|

+4

|

+6

|

Steel wire rope for lifting people

|

Nominal rope diameter Ø

|

Nominal diameter tolerance for rope with fibre/synthetic core | Nominal diameter tolerance for rope with steel core | ||||

| |

Unloaded

|

Loaded up to 5% of the minimum breaking load

|

Loaded up to 10% of the minimum breaking load

|

Unloaded

|

Loaded up to 5% of the minimum breaking load

|

Loaded up to 10% of the minimum breaking load

|

|

Mm

|

max. %

|

min. %

|

min. %

|

max. %

|

min. %

|

max. %

|

|

10

|

6

|

1

|

0

|

3

|

0

|

-1

|

|

>10

|

5

|

1

|

0

|

2

|

0

|

-1

|

|

Nominal rope diameter Ø

|

Two target results are distinguished, expressed as a percentage of the nominal diameter at a load of 5% or 10% of the minimum breaking load.

|

|

|

|

Rope ovality

|

The average diameter value is used for assessment.

|

|

Mm

|

max. %

|

max. %

|

|

<8

|

4

|

3

|

|

8 i wyżej

|

3

|

2

|