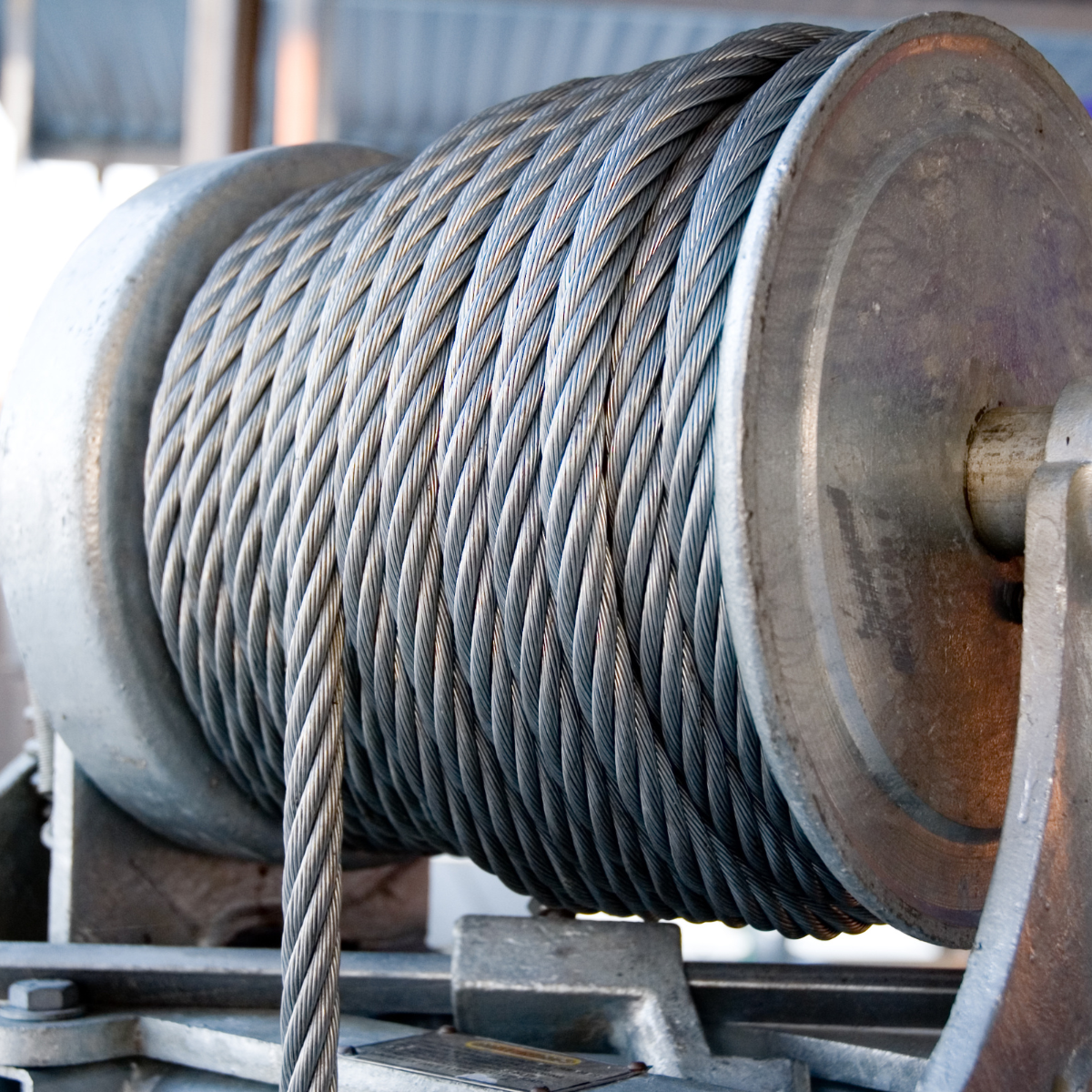

Steel wire ropes for winches

Winches are compact lifting devices used for lifting, pulling, or lowering loads. They are used in construction, industry, rescue operations, and mobile applications—for example on off-road vehicles or trailers. The steel wire rope, as the winch’s primary working element, must provide maximum safety, durability, and reliability in a wide range of operating conditions.

Where and how does the rope work in a winch?

-

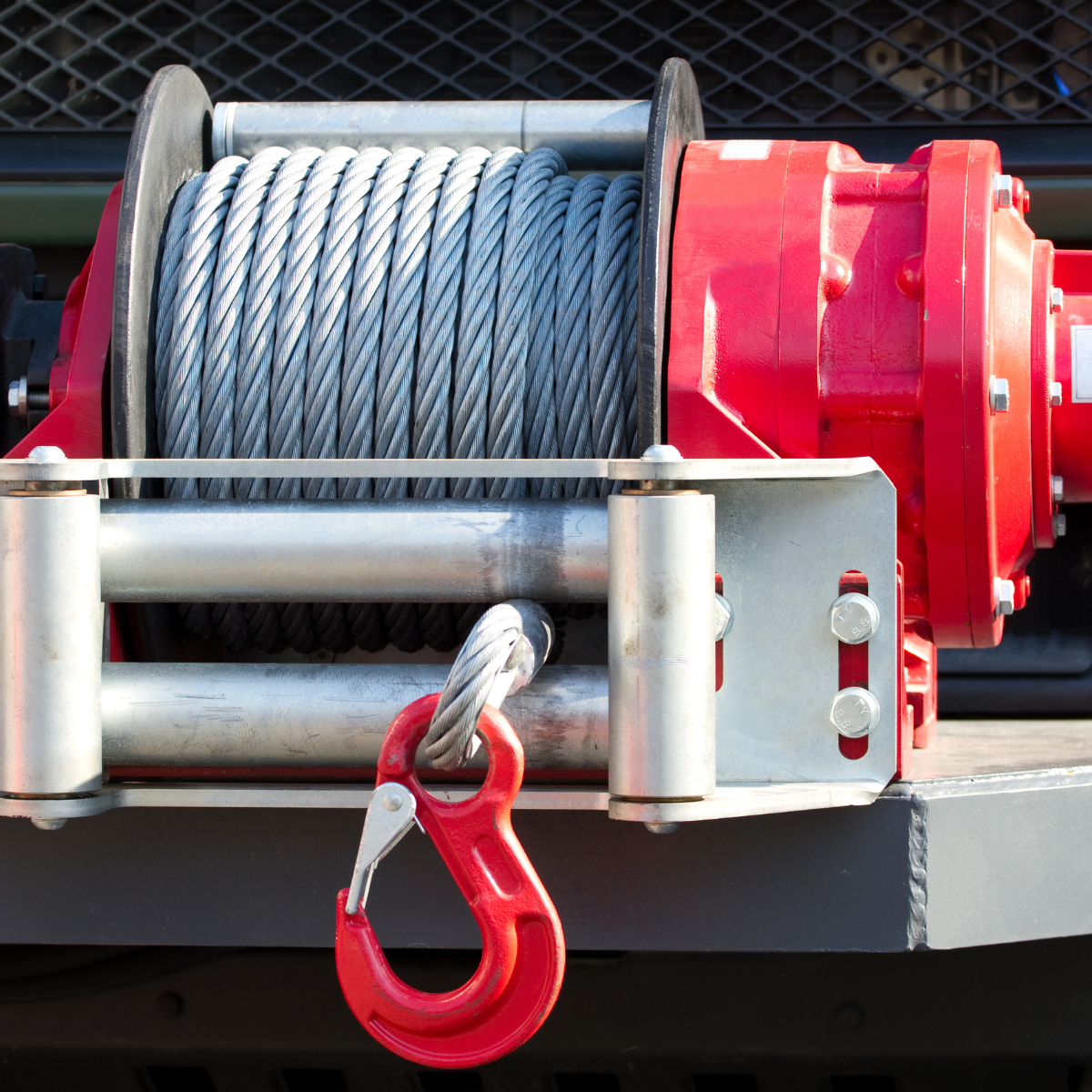

Electric and hydraulic winches – used for vertical or horizontal transport, most commonly on construction sites and in industrial plants. The rope must withstand intensive duty cycles and be resistant to bending on small drums.

-

Manual winches – lighter units used for gates, lightweight structures, or in field conditions. Here, flexibility and resistance to weather exposure are key.

-

Vehicle and rescue winches – used in demanding terrain, where the rope is exposed to mud, sand, water, and heavy overloads.

What characteristics should a winch rope have?

✔ resistance to bending on a small-diameter drum,

✔ compatibility with the winch pulling capacity and device parameters,

✔ good flexibility and easy handling/guiding,

✔ corrosion resistance—especially for outdoor applications,

✔ ability to operate through many cycles without loss of load capacity.

Most commonly chosen rope types for winches

- Steel core ropes (IWRC) – stiff and strong, used in industrial equipment.

- Galvanized or stainless steel ropes – resistant to moisture and corrosion, ideal for outdoor and rescue applications.

- Flexible fine-strand ropes (e.g., 6x36) – spool well on the drum and reduce the risk of damage in tight wraps.

Rope selection – what should you check?

📄 Check the winch’s technical/operational documentation (DTR) and the recommended rope diameter.

🔍 Pay attention to the permissible working load (WLL).

🧯 Match the rope construction to the type of work—pulling, lifting, or maintaining constant tension.